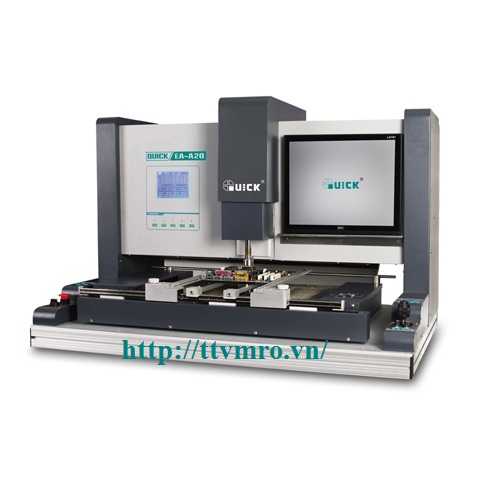

Features

1. Equipped with high automatic system, the operation of soldering, de-soldering, pick-up, and placement of chip can be completed by one-touch control.

2. The hot air BGA rework station is designed for multiple applications. No external air supply is required due to the large power brushless DC fan, temperature controlled by closed-loop sensor and the micro computer zero triggering.

3. There are seven temperature ranges for your selection. This machine can be used for light-reflecting BGA, multi-layer BGA and metal shield.

4. The heating system and the alignment system are well integrated. 5. Dichromatic optical prism alignment. Controlled by the jointed arm, the precision for process can be obtained.

6. During operation, the crossflow fan is provided to cool down the bottom heating area and the PCBs. The air speed is adjustable.

7. Through the QUICKSOFT interface, the control on the operating authorization and the profile analysis on the parameters such as preheating speed, peak temperature, heat preservation and rate of cooling can be realized.

8. Various types of nozzle are available for this hot air BGA rework station. The replacement is very easy.

Specifications

General Power | 6600W (Max.) |

Voltage | 220V AC 50Hz |

Hot Air Heating Temperature | 500℃ (Max.) |

Bottom Preheating Temperature | 500℃ (Max.) |

Power of Top Heater(hot air) | 1200W |

Power of Bottom Heater(hot air) | 1200W |

Power of Bottom Heater(infrared preheating) | 3200W |

Bottom Preheating Area | 550×450mm |

| Max. PCB Size | 600×500mm |

BGA Size Range | 2×2~60×60mm |

Placement Precision | ±0.025mm |

Air Speed of Side Cooling Fan | ≤3.5m³/min |

Camera | 22×10 times magnifying; Horizontal resolution: 480 lines; PAL format |

External K-type Sensor | 5pcs |

Communication | Standard RS-232S(Connected with PC) |

Weight | About 120kg |

Dimension | 1150(L)mm×800(W)mm×800(H)mm |