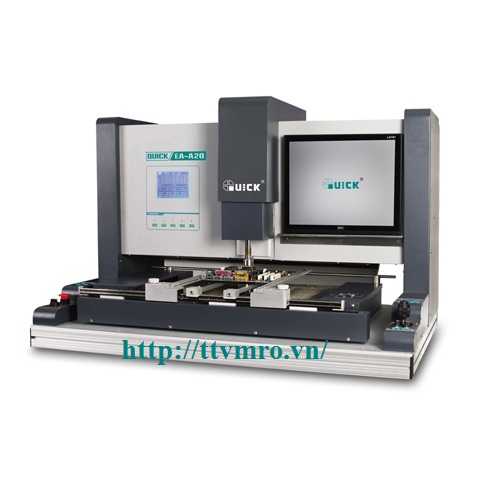

Features

1. The heating material for this hot air BGA rework station is imported. It can provide precise control on the reworking process.

2. The top heater is heated by the hot air. For the bottom heater, it is designed by integrating the infrared heating and hot air heating.

3. The heating system of the top and the bottom heater can be controlled through programming to guarantee the accurate temperature and the uniform heating distribution.

4. Various kinds of nozzles are available for this product. Additionally, the replacement of the nozzle is quite easy.

5. The high power brushless DC fan is used to cool down the bottom heating area and the PCB during processing. Meanwhile, the air speed can be adjusted.

6. The hot air BGA rework station can be controlled through QUICKSOFT.

7. The large volume hot air with constant temperature is obtained with the large power brushless DC fan, temperature controlled by closed-loop sensor, and micro computer zero tripping.

Specifications

General Power | 4200W (Max.) |

Voltage | 220V AC 50Hz |

Power of Top Heater(hot air heating) | 800W |

Power of Bottom Heater (hot air) | 800W |

Power of Bottom Heater(infrared preheating) | 1600W (400W×4, infrared heating plate) |

Air Speed of Side Cooling Fan | ≤ 3.5m³/min |

Hot Air Heating Temperature | 500℃ (Max.) |

Infrared Preheating Temperature | 500℃ (Max.) |

Bottom Preheating Area | 300×350mm |

| Max. PCB Size | 350×400mm |

External K-type Sensor | 3pcs |

Communication | Standard RS-232S(connected with PC) |

Weight | About 30kg |

Dimension | 750(L)mm×650(W)mm×520(H)mm |