Features

1. The top heater of the machine is heated by hot air. The bottom heater is heated by infrared ray and hot air as well.

2. The size of the optical alignment prism is 50×50mm.

3. The hot air BGA rework station can memorize the soldering and de-soldering height, placement height and alignment height.

4. This machine can be equipped with various kinds of nozzles.

5. The crossflow cooling fan is provided with this product to cool down the bottom heating area and the PCB during operation. The air speed can be controlled through programming.

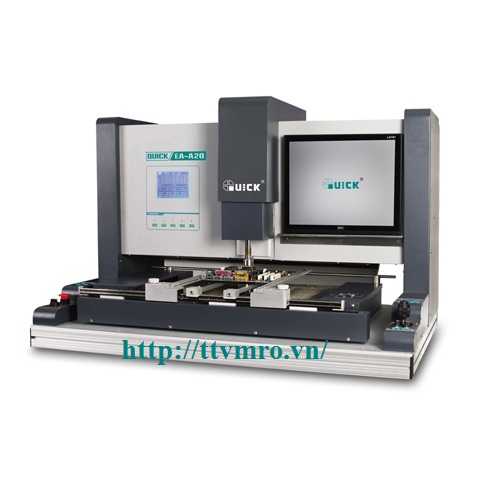

Specifications

General Power | 4200W (Max.) |

Voltage | 220V AC 50Hz |

Power of Top Heater (hot air) | 1200W |

Power of Bottom Heater (hot air) | 1200W |

Power of Bottom Heater (infrared preheating) | 1600W |

Air Speed of Side Cooling Fan | ≤ 3.5m³/min |

Hot Air Temperature | 400℃ (Max.) |

Infrared Preheating Temperature | 400℃ (Max.) |

Bottom Preheating Area | 400×400 mm |

| Max. PCB Size | 420×450 mm |

BGA Size Range | 2×2~60×60 mm |

Placement Precision | ±0.025 mm |

Placement Force | |

Camera | 12 /300mA; 22×10 magnifying; Horizontal resolution: 480 lines; PAL format (line-by-line inversion) |

LED Light | Top lighting: blue LED ; Bottom lighting: orange LED (brightness adjustable) |

Communication | USB (Connected with PC) |

External K-type Sensor | 5pcs |

Weight | About 55kg |

Dimension | 810(L)mm×675(W)mm×835(H)mm |